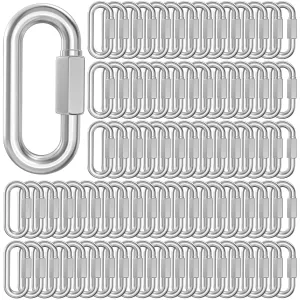

- A unique Tune-o-matic style bridge and matching "stop" tailpiece combo for solidbody guitar

- The Gotoh 510 Tune-o-matic Bridge is designed for absolute stability

- The Gotoh 510 "Stop" Tailpiece pivots on unique ball-end threaded locking studs, for straight string pull

- The bridge is lightweight for distinctive tone, and both mount on Allen height-adjustable studs in threaded bushings

- See Product Description for measurements and specifications

Modern design locking bridge and tailpiece! A unique Tune-o-matic style bridge and matching "stop" tailpiece combo for solidbody guitar. The bridge is lightweight for distinctive tone. Both pieces mount on Allen height-adjustable studs in threaded bushings.

SAVE when you buy the bridge and tailpiece set!

The Gotoh 510 Tune-o-matic Bridge is designed for absolute stability. Allen screws lock the individually adjustable saddles, height adjustment studs (this bridge uses no thumbscrews) and the overall bridge intonation angle. The result is better sustain, rock-solid intonation and improved string energy transfer. The saddles have helpful starter grooves to guide your notching files. Made of zinc.

Gotoh 510 Tune-o-matic Bridge Specs:

- String spread: 2-1/16" (52.58mm)

- Saddle radius: 12" (304.80mm)

- Post spacing: 2-29/32" (73.91mm)

- Post threads: M8 x 1.25mm

- Drill 7/16" (11mm) holes for the bushings

The Gotoh 510 "Stop" Tailpiece pivots on unique ball-end threaded locking studs, for straight string pull. Spring retainer clips prevent the tailpiece from falling off when the strings are removed, to save your guitar's finish from accidental dings. Made of lightweight aluminum for distinctive tone.

Gotoh 510 "Stop" Tailpiece Specs:

- String spread: 2-1/16" (52.58mm)

- Post spacing: 3-1/4" (81.79mm)

- Post threads: M8 x 1.25mm

- Drill 7/16" (11mm) holes for the bushings

Tech Tip: Nut slotting files work great for metal saddles. Choose your file size as you would when slotting a nut: use the same gauge as the string, or a few thousandths larger. After filing to the desired depth, we suggest polishing the slot with abrasive cord to remove file marks and burrs.